Power tools can be a great advantage, especially if you do a lot of DIY work or are undertaking large projects.

An impact driver and impact wrench can seemingly be indistinguishable to the individual who is not as well-versed in power tools. But what makes each of these power tools unique, and which one should you be using for particular tasks?

Understanding these details can help you maximize the efficiency of each tool. Of course, there are similarities, but the difference between each tool is where they individually shine. This guide will help you understand where each product can be used to its utmost potential, and help you make the most informed purchase.

With that being said, let us get into it!

Impact Driver vs. Impact Wrench

What Is An Impact Driver?

In order to understand what an impact driver is, imagine a standard drill but with more power behind it. This is essentially what an impact driver is; a tough, durable drill that can break through a variety of tough materials.

What is probably the key feature of an impact driver is the high rotational torque it provides. Beyond just a rotational motion, it is also able to move in an axial motion as well. This is where the “impact” in impact drivers comes from.

- Compact (5.55 front to back), lightweight (2.8...

- 3 LEDs with 20-second delay after trigger release,...

Using this tool is similar to combining the motion of a hammer and drill into one. The power from the rotation and hammering blows together to make quick work of any tasks involving driving. It is easy to see how effective this power tool can be in fastening screws and nails into various materials.

Additionally, an impact driver is able to drill regular holes with greater efficiency than a standard drill. An ordinary power drill only has rotational torque and overheats when used on rigid surfaces. On the other hand, an impact driver is able to pierce through the surface with the rotational torque while also hammering away to maintain a proper temperature.

These drivers use a standard ¼” hex collet to secure the drill bits, a similar setup to regular power drills. As such, the drill bit of an impact driver can be interchanged to complete various tasks.

When Should An Impact Driver Be Used?

If you want to get the absolute most out of an impact driver, it is advised to use it in tasks involving fasteners, like screws and nails, or drilling into hard surfaces.

These two use cases are what this power tool was designed for and can give a quality outcome with minimal effort. Taking each use case in turn, we will demonstrate just how effective an impact driver can be in its performance.

For drilling purposes, the driver uses a hexagonal shank drill bit. This unique bit design coupled with the percussive force from the power tool makes for a powerful force. Altogether, the hammering motion allows the drill to pierce through more rigid materials while the rotating hexagon bit removes the chipped fragments.

Additionally, attaching a fastener into materials is a much easier experience when using an impact driver. Using a standard power drill to fasten a screw can be tiring and cause stress on the motor of the drill. An impact driver, however, removes this strain on your hands and the drill’s motor.

Another use case where this power tool shines is when handling large screws. If a regular power drill was to be used to drill in a large screw, such as a self-threading screw, it would be a complicated process. What’s more, it could result in an injury if not done carefully.

Alternatively, using an impact driver allows the screw to be hammered into the material while being drilled at the same time. The length of the screw is not an issue as the tool’s back-and-forth axial motion secures it into the hardwood.

Overall, the impact driver stands high above a regular power drill in terms of efficiency and ease of use. The combined motions of this power tool make for an effective combination that increases productivity.

Benefits Of Impact Drivers

An impact driver clearly performs well when handling fastening and drilling tasks. Beyond this, there are other areas where it performs exceptionally.

As impact drivers have a similar motion as drills, the torque involved when using one is noteworthy. The impact driver has a range of 1,500 to 1,800 in.lb. of torque. If a standard drill were to perform at such a high level, there would be considerable risk to the handler. A high torque can twist the user’s wrist while using the drill, offsetting the drill and potentially causing injury.

Reactionary torque is controlled in the impact driver by the axial motion that counteracts the torque. By removing this risk of slipping and injury, the impact driver is able to operate at higher RPM (rotations per minute). This makes it perfect for handling more rigid materials.

A high RPM is suitable when drilling into tough materials but not as much for softer surfaces. High RPM on a soft material can damage the surface, so an impact driver that has a variety of speed settings can increase its versatility.

Another benefit of using an impact driver is its ease in removing screws and nails. This power tool can easily drill these fasteners into rigid materials, but it can also get them out just as easily. Thanks to the axial motion of the driver, the screws are pulled out quickly and with minimal damage to the material itself.

When it comes to the footprint of the impact driver, it is pretty compact. Fitting it into your toolbox is not challenging, and it can be easily carried in one hand. Additionally, tight spaces or hard-to-reach spots are an easy fit for the impact driver.

Drawbacks Of Impact Drivers

At this point, it may seem like an impact driver is the power tool to end all tools, but it does come with its own caveats. There are some features about it which may not make it suitable for just anyone.

One drawback to using an impact driver is most models are usually cordless in design. This means you will have to have to charge a battery and maybe have one spare as a backup. While it may not be a deal-breaker for some, it should still be noted that this driver involves an extra step of maintenance.

Another drawback to using an impact drill is the high noise levels involved. As it involves two different types of motions, it can reach an uncomfortable noise level. It is suggested that earplugs be used while working with an impact drill to protect your hearing.

Additionally, there is no clutch built into an impact driver, unlike a regular power drill. A clutch functions as a limiter to how deeply the drill goes into the material. This lack of control in the impact driver can result in drilling too deep. There should be a constant presence of mind when using one to ensure you don’t drill more than intended.

Impact Driver: Pros & Cons

- Little to no rotational torque

- Easy portability with light weight

- Drill bits can be interchanged for versatility

- Compact design to reach tight spots

- Powerful torque motor

- Loud noise level

- No built-in clutch

What Is An Impact Wrench?

Although it shares a similar name with an impact driver, impact wrenches have a completely different function.

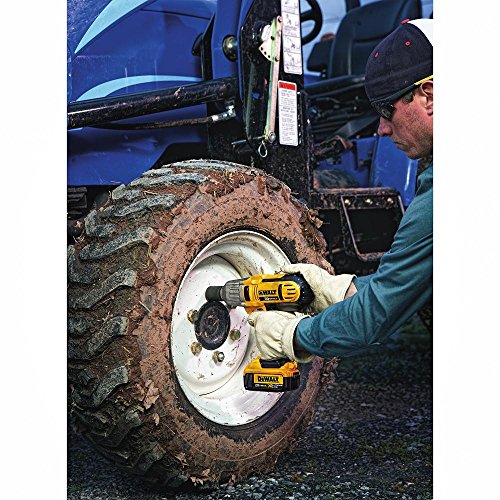

This power tool is used to loosen or tighten lug nuts and bolts with incredibly strong torque for the most secure fit. Also known as an impact gun, it has a more substantial power than an impact driver; more power than is generally needed for a typical household.

To give you a frame of reference, an impact wrench has more torque than an impact driver and a regular power drill put together. The torque of this particular tool is measured not in inches per pound but feet per pound! That is an exceptional amount of force in such a small package.

- 1/2 inch cordless impact wrench has 345 ft-lbs of...

- DEWALT 1/2 inch impact wrench comes with 1/2-inch...

With so much power in a small, compact power tool, the question of what powers this wrench comes up. There are a few variants of impact wrenches available, differing in their power source.

Types Of Impact Wrenches

Depending on the context and what is being fastened or loosened, the power sources of an impact wrench can vary. These different power sources have their own benefits that allow the impact wrench to be used more easily in a particular situation.

Corded

One of the most basic impact wrench models, this power tool needs an electrical socket to operate. The corded design saves some space on the impact wrench itself as there is no need to accommodate an onboard battery.

Cordless

A cordless impact wrench is recommended for increased portability and maneuverability. It can be used anywhere without the restriction of a cord or power outlet availability.

One caveat of using a cordless model is the extra weight or bulk that comes with the attached battery. While certain models may offer an extra battery, backups may have to be purchased separately.

Moreover, the maintenance of cordless impact wrenches has the added step of charging the battery. A low battery may not provide as much torque as a fully charged one, so maintaining optimal levels is key.

Air-Powered (Hydraulic)

This type of impact wrench is most commonly seen in automobile repair shops and garages. Due to the high pressure and power from the pneumatic impact wrench, it is helpful in removing lug nuts on a car in seconds.

This type of impact wrench has a pipe attached to one end, which feeds compressed air into it. By releasing and controlling the air pressure, the wrench is able to exert a high amount of torque.

Being such a powerful tool with a specific use case, the air-powered impact wrench is not commonly used in households. Professionals in various industries will find more use for this type of impact wrench.

Hydraulic

One of the lesser common types of impact wrenches, the hydraulic wrench, uses a fluid system to create torque. It is commonly used in mining and industrial as well as underwater applications. Clearly, this type of impact wrench is not for the everyday worker.

When Should An Impact Wrench Be Used?

Impact wrenches are not usually found in homes as the amount of power it has is overkill for the purposes around the house. It is more commonly seen in the automobile industry or in factories to secure bolts and fasteners tightly. One could say it is an industry-level power tool.

Construction work and assembly lines are two other unique cases where an impact wrench is used. It is clear to see that an impact wrench does not have as many practical applications for the everyday user at home.

However, it does come in handy for specialized cases where a regular wrench or other power tool is insufficient. Removing rusting bolts or lug nuts that are too tight on a car are two unique cases where the power of an impact wrench could come in handy.

Besides these small instances and unique cases, there are not many scenarios where an ordinary worker would use an impact wrench. Outside of industrial uses, buying an impact wrench is not popularly justified as the amount of power is not required to fulfill most tasks.

Benefits Of An Impact Wrench

Impact wrenches have an incredible amount of power behind their small build. In fact, they have more torque than an impact driver and standard power drill put together! This amount of power to perform a single tightening or loosening is more than enough to get the job done.

Where the impact wrench shines is in its incredible strength. It can undo any fastener with ease, whether it is used on rusted bolts or the tightest of lug nuts. Simply firing the trigger and holding it steady will get the bold undone in a matter of seconds.

When using an impact wrench, there is a focus on reducing the risk of injury. Working at such a high RPM and power, an injury caused by this power tool could be fatal. As such, reducing the risk of any strain or injury is paramount.

Wrist and strain and fatigue are two factors that are eliminated by the impact wrench’s design. The torque does not cause the power tool to slip or jump out of the user’s hands. A comfortable and steady grip can be maintained at all times while using the impact wrench.

Although you will never need all four types of impact wrenches, there are still a variety of types to choose from, each with its own strengths and benefits. Depending on what you want the impact wrench to do, or if you have certain working conditions, you can pick the most suitable type for you.

Drawbacks Of An Impact Wrench

As it is such a specific power tool, the impact wrench does not have as much versatility when it comes to performance. It is designed for one task and one task only. Of course, the efficiency and speed at which it performs are astonishing, but it is useless unless a situation arises where it would come in handy.

As a result, these impact wrenches are not a common tool found in a DIY workshop or household. They are more widely used in industrial situations where they can be effectively utilized to their full capabilities. Construction and working on cars are just a few areas where an impact wrench would actually come in useful.

With such a high torque and RPM, the impact wrench is bound to generate quite a lot of noise. So much so that earplugs are recommended if you are using one. Proper safety measures should be closely followed; working with such powerful machines can be dangerous in an accident.

Additionally, beyond earplugs, safety glasses and gloves should be worn as well. The high speed at which the impact wrench moves does not allow much leeway in operation. There is little to no room for mistakes when using such a power tool.

Amateurs and novices are advised not to use an impact wrench as the room for error is large. An improper positioning of the wrench can send the lug nut flying or cause damage to the motor. It is best to have an experienced worker handle the impact wrench to ensure no such accidents occur.

Impact Wrench: Pros & Cons

- High amount of torque created

- Reduces fatigue and wrist strain

- Can work within seconds

- Four types available

- Loud noise levels

- Specific use-case scenarios

- It can be dangerous if used by an amateur

Comparing Impact Drivers And Impact Wrenches

In order to understand which of these two power tools is the better purchase for your needs, we will compare each based on various factors. These factors can affect how a particular power tool performs.

Depending on what you are looking for, you can use these factors to judge which is the more suitable option.

Torque

In terms of how much rotational power each tool provides, the impact wrench comes out on top. Both have an exceptional amount of torque but also have unique applications .

While the impact wrench may have more torque, there are even more powerful impact drivers having 18V or 20V of power. These impact drivers can reach 167 ft-lbs. of torque, as compared to the starting baseline of 100 ft-lbs. of the impact wrench.

On the other hand, impact wrenches can reach over 1,000 ft-lbs. of torque in some extreme use cases. However, for the average user or car garage shop, a simple 200 ft-lbs. is enough to get the job done.

Speed

Torque and RPM or speed are vastly different in terms of the power each provides. Where torque handles the rotational force, RPM involves how fast the actual bit is spinning.

Impact drivers are generally faster than impact wrenches, which focus more on power rather than speed. A high-end impact driver can reach speeds of up to 3,600 RPM, while a quality impact wrench comes in at just under 2,000 RPM.

However, pneumatic impact wrenches used in shops and garages have a considerably higher RPM than that of an impact driver. This specific type of impact wrench can reach an RPM of up to 8,000 and above!

User Experience

Both the impact driver and impact wrench have incredible power and speed, more than the average user may even need. However, where they differ the most is in their application and versatility in performance.

Impact drivers have a wide range of applications in the home space, be it as a DIY project or renovations, or simple carpentry. Thanks to their ease of use and versatility, they are more applicable in various situations as compared to an impact wrench.

These impact wrenches have exceptional power, almost too much for the typical household. It is easy to overtighten and potentially break a screw when securing it with an impact wrench. What’s more, the amount of power is unnecessary for the uses around the home.

Of course, there are measures to prevent over-tightening in an impact wrench, but these precautions can be costly and not worth the investment. For many, it is too specific of a use case to justify the money being spent when a regular wrench is sufficient.

Sizing

Depending on the manufacturer and model, the size of an impact driver and wrench can be very similar. In terms of the weight of the power tool itself, impact drivers tend to be lighter than a cordless impact wrench.

With impact wrenches, an increase in its power output means the tool becomes bulkier and heavier. One exception is the pneumatic impact wrench, which can be lighter than an impact driver thanks to its simple design and lack of a handheld motor.

Power

For the impact driver, it is powered either by an electrical outlet or an attached battery. While both perform well enough, the cordless option is more popular.

In modern power tools, there is an increasing number of cordless options being developed. While a corded option is always viable, the vast majority of models available today are cordless. Some of the most common voltages used by power tools today are 12V, 18V, and 20V. Of course, there are more options available that offer better control or more power.

As for the impact wrench, there are a number of types that use various power sources to create torque. Perhaps the most common one is the pneumatic or air-powered variant. These impact wrenches are widely used in garages and car shops to quickly remove and attach lug nuts on a tire.

Impact Driver vs. Impact Wrench Buying Guide

With advancements in technology and innovation, there are a large number of extra features a power tool can have. To maximize your value for money, you should be aware of what to look out for in a good power tool.

Power tools don’t come cheap, so if you are paying top dollar for one, it only makes sense that you should get the absolute best. Here are some factors to keep in mind before making a decision on what model to get.

Weight

Using power tools can become tiresome very quickly with their motor and the fast-moving parts. To ease this strain, the weight of the power tool is an important feature to look out for. Find the perfect balance of weight and quality that works for you to have the best user experience possible.

Having a lighter power tool can help you use it for an extended period while maintaining your quality of work. Heavier models may provide more power but can be cumbersome to use in the long run.

Safety

How safe a power tool is can make or break a decision to purchase a particular model. There is no point in taking risks and potentially hurting yourself or damaging the material being worked on.

An impact driver and wrench both have unique safety features that vary depending on the model and manufacturer. One common safety feature is an automatic shut-off to preserve the motor when it begins getting too hot. Another auto shut-off is designed to preserve battery life once it is fully charged (only in cordless power tools).

Another safety feature that can come in handy is built-in dust protection. This particular design is able to keep dust and debris from flying into the inner mechanism of the power tool and causing damage or malfunction.

Additional Features

New innovations such as attached LED lights and Bluetooth connectivity have brought a new level of interaction to power tools. These features are not necessary to get an effective performance out of the power tool, but they can make the experience easier.

For example, the LED lights on an impact driver can help you see into tight places or illuminate your working area for a more precise drill. Additionally, using Bluetooth on a power tool may seem like too much, but it can help keep track of various factors. How much the drill has been used, when it should be maintained or charged, and other factors to maintain the tool are all communicated via Bluetooth.

Beyond these innovations, there are extra features that some manufacturers include, such as replaceable batteries and a variety of drill bits. Having a starter kit included with the power tool can save you extra expenses to purchase a case and accessories.

Impact Driver vs. Impact Wrench FAQ

Q1. What is torque?

Torque is a unit of measurement for how much rotational power an object has. This is usually measured in inches per pound (in-lb.) or foot per pound (ft-lb.). The amount of force needed to move an object in a rotational motion is the amount of torque it has.

Q2. Does an impact driver wear out?

As is the case with many power tools, an impact driver can potentially be worn out. To keep this from happening and extend the lifespan of your tool, proper maintenance should be taken. Follow the precautions and instructions given by the manufacturer, and you shouldn’t run into any problems.

Q3. What are the downsides to using an air impact wrench?

Operating an air impact wrench may seem like an excellent investment with its lightweight design and incredible power. However, there are additional costs that must be factored in before purchasing one. You will need a compressor to feed the air into the nozzle and a hose to connect both of them. Without either of these, the impact wrench will be unable to function.

Q4. What precautions should you take when using a power tool?

Beyond the built-in safety features of each power tool, a few preventive measures should always be taken to avoid personal injury.

Wearing protective eyewear and earplugs is an absolute must when working with power tools. They can spit out dust at high speeds and reach noise levels that are harmful under regular exposure. Safety glasses and earplugs are the best way to counteract these potential risks.

Additionally, your clothing should not have any hanging pieces, such as jewelry or loose ends. These bits can get sucked into the power tool or block your view while you work.

Finally, as a general rule of thumb, you should always be aware of how a power tool works before using it. If you are unsure of anything, read the instruction manual thoroughly or have an expert guide you along.

Conclusion

With all these factors and features being considered, what then is the best power tool to invest in? Well, depending on the type of work you will be doing, either tool will give different results.

An impact driver will serve you well for simple DIY tasks, general drilling, and screwing fasteners in. On the other hand, if you regularly work with bolts or need to fasten screws quickly, an impact wrench is the better option. Moreover, it provides more power, so stubborn and rusty bolts are not an issue.

If there is space in the budget for both, they are equally effective in doing what they were designed to do. However, the impact driver will have more versatile applications in a household than an impact wrench.

At the end of the day, each power tool is worth the investment; hopefully, now you can make a much more informed decision.

Related Articles

11 Best Drill Bits for Hardened Steel

9 Most Powerful Cordless Drills

Simply the Best Cordless Power Tool Brands